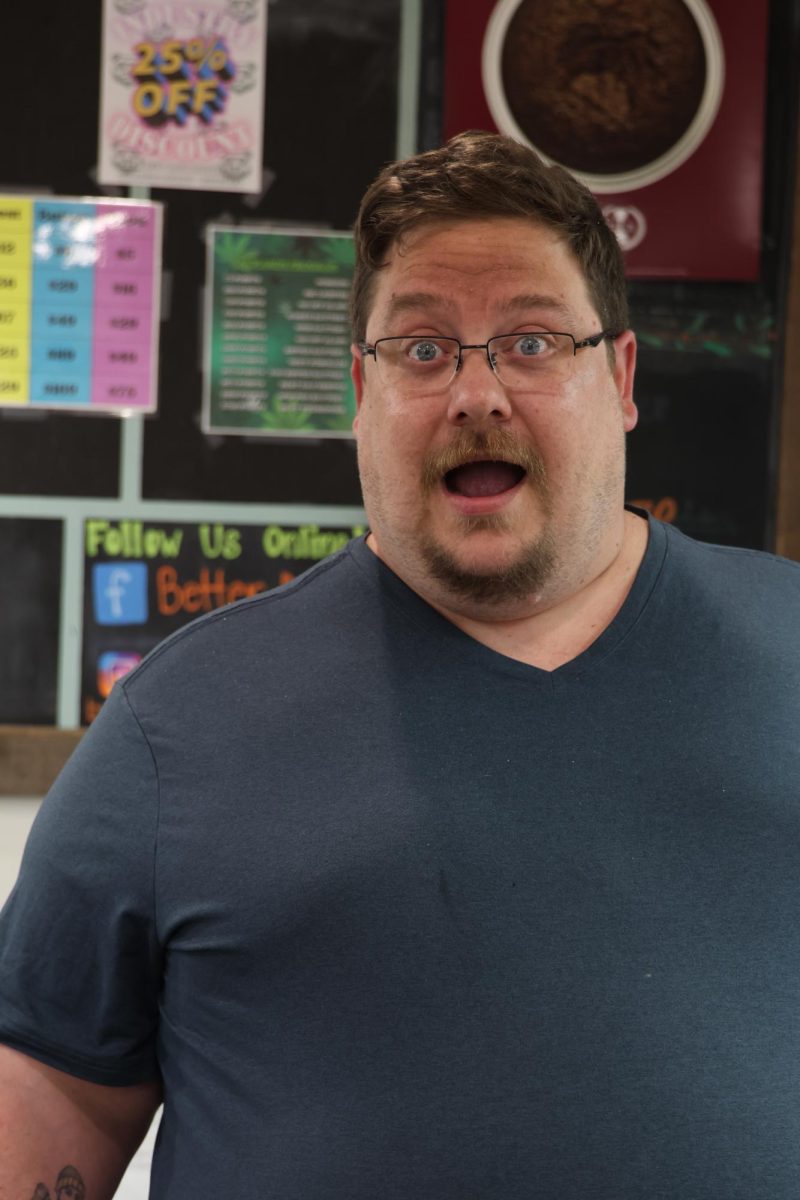

Did you know that more than seven billion trees are cut down each year to provide us with paper products alone? Did you know that instead of cutting down all those trees, paper can be made out of hemp? And did you know that hemp paper is sustainable and can be entirely tree-free? Matthew Glyer has spent years of his life grappling with these questions, and when he opened Hemp Press in 2013, he became the proprietor of the first exclusively hemp paper print shop in the nation. Hemp Press is the only printing company of its kind, and it’s located right here in Eugene! The company specializes in creating and designing hemp-based packaging for hemp and marijuana-based products, labels, business cards and their trademark Crutch Cards.

“Hemp paper is controversial,” Glyer says. “The paper mills don’t want to make craft paper and the printers don’t want to print with it.” Glyer says this is mostly due to the fibrous nature of craft papers and the particularity of hemp paper, which is made from the core of the hemp plant.

“Most printers run the risk of having a piece of hemp break off and completely ruin the machine, but ours is equipped for that.” It took Glyer four years to figure out how to print on hemp paper, and now that he has cracked the code, he sees the opportunity to incorporate hemp paper into the economic and agricultural norm.

“Our big goal is to keep manufacturing in the United States and to source the fiber from the United States,” Glyer says.

Previously, the primary source for hemp fiber was Canada, where the government both subsidized and funded the industrial hemp industry. However, since the funds for hemp research and production dried up a few years ago, hemp growers and enthusiasts in the U.S. have been searching for a way to bring the industrial hemp industry to native soil.

“Currently, we do not really have the infrastructure in the U.S. to process hemp fiber,” Glyer says, expressing a desire to inspire farmers to actually grow hemp. However, the farmers need a guarantee that the hemp crops they grow will be turned into products that people will regularly buy and use. This is a promise that is becoming easier to make with the introduction of hemp clothing, beauty products and supplements to mainstream grocery stores like Costco and Whole Foods.

Glyer and his colleagues want to turn hemp into a mainstream agricultural commodity, and they hope their printing business will help people see that hemp is a useful and sustainable crop that could help save the planet.

Historically, hemp was widely used to produce products such as rope, clothing and even classic Henry Ford automobiles. However, following Prohibition, the hemp industry was shut down due to its association with marijuana and other illicit substances. This history of government restrictions makes it exceedingly difficult to restart the industry in the U.S. today.

“Part of getting hemp back in the market is branding,” Glyer says. “Hemp-based branding ought not to scream ‘weed,’ so our branding services aim to produce more subtle designs that connect with a broader market.” Hemp Press prints packaging for beauty products, lotions, smoking accessories and other marijuana-related businesses.

“Ultimately, hemp is good for the planet,” Glyer says. “That’s why we need to keep growing it and keep making everyday things out of it if we can.”

He’s right—hemp is naturally resilient, thus eliminating the need for most pesticides and herbicides. According to a study done by the American Chemical Society, hemp also cleans the soil, absorbs CO2 from the soil as it grows and can be used as a substitute for many non-sustainable products. This includes traditional plastics, building materials, and—of course—paper.

Instagram: @hemp.press

Website: www.hemp.press

Email: contact@hemp.press